Ultra-high temperature Logging-While-Drilling tools and Pressure-While-Drilling (PWD) applications in high temperature geothermal wells.

Abstract

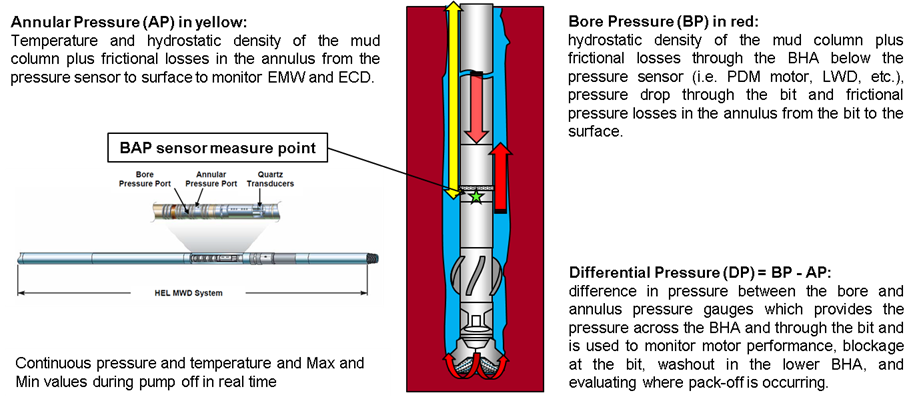

The use of directional drilling in a geothermal is usually dictated by geological targets, for example to intersect as many formation fractures as possible, or lease boundaries, institutional, legal, or topographic issues, and allows to drill several wells from one prepared site avoiding collisions. The difficulties inherent in directional drilling are aggravated in geothermal wells because both the electronic tools and elastomer elements in the motors are susceptible to high temperature. We will present new set of high-temperature Logging-While-Drilling (LWD) and Pressure-While-Drilling (PWD) technologies for operating unshielded electronic components up to 210ºC. In particular, the BAP tool, a high temperature PWD sensor that provides bore and annular pressure and temperature, was used in some high enthalpy deviated geothermal wells where lost circulation was expected, mainly related to the presence of natural highly productive fracture system.

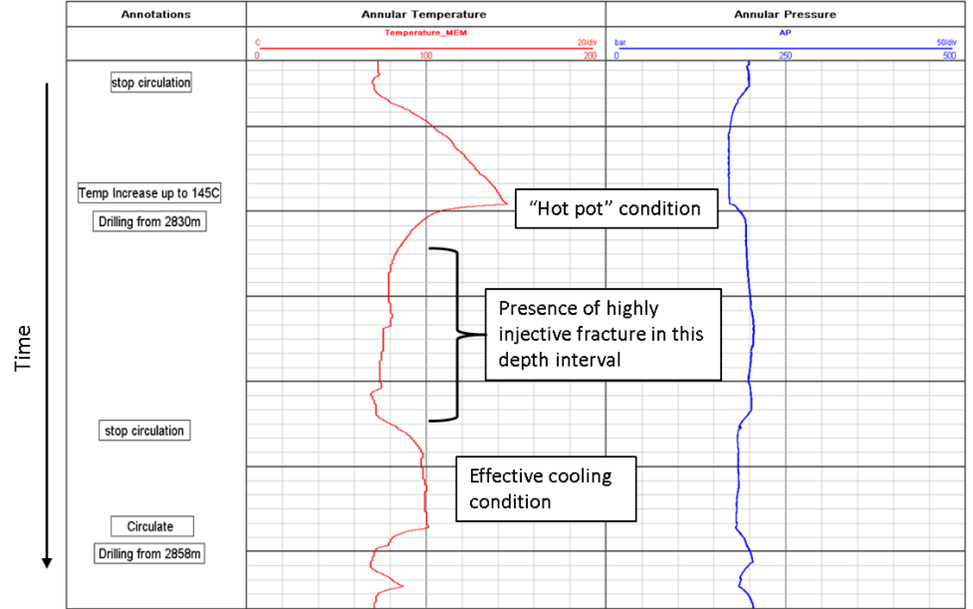

In addition to the applications commonly used in oil and gas wells, the real time and cost-effective measurement of downhole pressure and temperature was attempted to be used to better understand hydraulic conditions of the reservoir, improve accuracy in fracture characterization and position, and prevent downhole equipment damage and NPT. In particular, the combined analysis of downhole pressure and temperature trends, measured by the BAP sensor, was used to discriminate between “open” versus “closed” circulating system (or “hot pot”) and position the losses and fracture, which are all valuable data for drilling and completion plans. Although there are multiple variables to take into consideration, the concept proves to be valuable and deserves further discussion and case history.